Geopolitical Implications and Supply Chain Restructuring

The motivation behind this level of localized manufacturing transcends mere efficiency; it is fundamentally about securing national technological advantages for the coming decades.

Bolstering National Technological Sovereignty

A core stated reason from OpenAI’s leadership is the belief that the infrastructure underpinning advanced AI represents a “generational opportunity to reindustrialize America.” This initiative is explicitly framed as a geopolitical measure to ensure the core technologies defining the next industrial age are physically constructed within the United States. By securing a domestic pipeline for everything from the racks to the power delivery, the nation strengthens its technological sovereignty in a domain rapidly becoming central to economic and military competitiveness. The effort is designed to foster a more resilient, self-sufficient domestic ecosystem, insulating critical AI deployment timelines from international supply disruptions—a narrative that resonates strongly with current national policy priorities.. Find out more about OpenAI Foxconn domestic AI hardware manufacturing.

Mitigating International Trade and Tariff Headwinds

The explicit focus on manufacturing within Foxconn’s established U.S. footprint serves a dual purpose: expanding domestic capacity while simultaneously addressing potential trade friction. In an era where international trade policies and tariffs can introduce huge cost volatility, anchoring final assembly and critical component manufacturing within U.S. borders provides a necessary layer of insulation. This strategy ensures that the accelerating demand for AI infrastructure can be met with more predictable costs and timelines, reducing exposure to external economic shifts that could otherwise hamstring the rapid deployment schedules essential for winning the race for artificial intelligence. This move is a direct realization of policy desires for increased onshoring of high-value manufacturing.

Synergistic Manufacturing Modernization Efforts. Find out more about OpenAI Foxconn domestic AI hardware manufacturing guide.

Foxconn isn’t just bringing its assembly lines to the U.S.; it’s bringing a modernized, smarter way of building. This collaboration is accelerating internal initiatives that will redefine electronics assembly for the AI era.

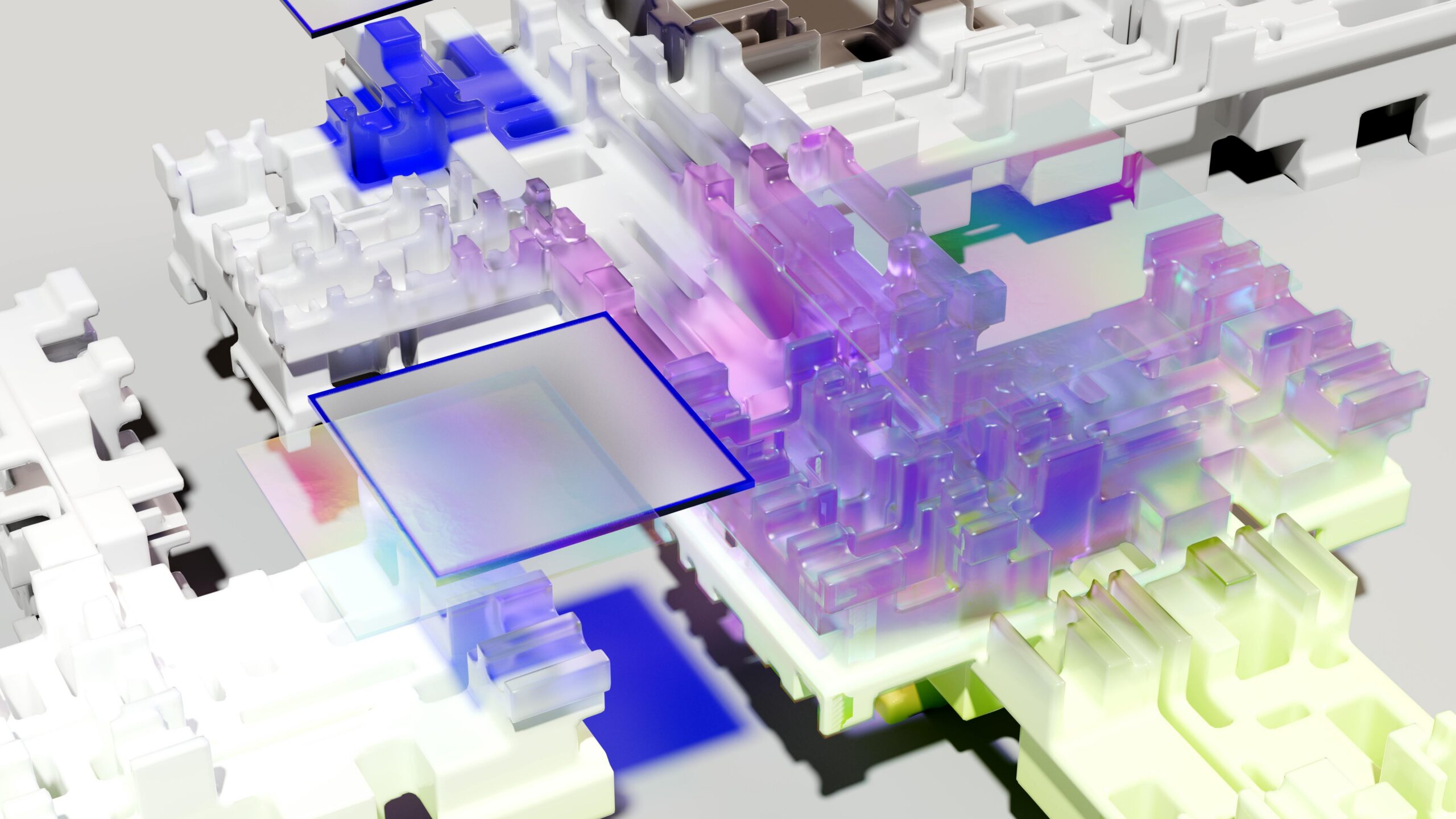

The Integration of Robotics and Intelligent Automation

The OpenAI partnership is a catalyst for Foxconn’s broader modernization. Specifically, the company has announced a separate but highly complementary joint venture with Intrinsic, an Alphabet subsidiary specializing in robotics. This initiative is dedicated to establishing general-purpose robotics and sophisticated automation across Foxconn’s manufacturing facilities, including those designated for AI hardware production. The goal is to infuse every part of the process—from initial assembly and quality inspection to machine tending and internal logistics—with AI-enabled tools. This creates a powerful feedback loop: they leverage the very technology they are helping to build infrastructure for, making AI drive the efficiency of AI hardware production.

The aim is a shift away from rigid, inflexible automation—which is slow to change when a new rack design drops—toward intelligent robotics that can adapt rapidly. This modernization effort is about creating factories that are fundamentally more adaptable, skill-based in their new automated approach, and critically, highly scalable to meet the massive demand projections for AI compute hardware throughout the latter half of the decade.. Find out more about OpenAI Foxconn domestic AI hardware manufacturing tips.

Enhancing Production Flexibility and Precision

The joint development with Intrinsic is focused on overcoming the traditional hurdles of high-volume electronics assembly. By deploying Intrinsic’s AI-driven platform, which includes advanced computer vision, Foxconn aims for unprecedented production flexibility. This means manufacturing lines can pivot quickly to iterative design changes flowing from the OpenAI collaboration without needing massive, months-long retooling efforts. This new level of precision and adaptability is what will allow them to meet the promised volume ramp-up.

Future Trajectories and Industry Significance. Find out more about OpenAI Foxconn domestic AI hardware manufacturing strategies.

If the partnership’s initial goals are met, the ripple effects will be felt far beyond the walls of Foxconn’s new domestic facilities. This is about setting a new industrial precedent.

Projections for U.S. Manufacturing Capacity Expansion

This collaboration signals a tangible commitment to scaling U.S. manufacturing output to meet the immense appetite for AI infrastructure. Foxconn Chairman Young Liu has outlined expectations to significantly increase operational capacity, targeting the assembly of as many as two thousand server racks per week within its American facilities by the calendar year 2026. This aggressive ramp-up is a direct measure of the expected hardware volume needed. For context, Foxconn can currently manufacture 1,000 racks per week. Establishing this dedicated, high-volume domestic production capability for complex AI systems represents a major industrial footprint shift, moving large-scale, complex assembly closer to the center of AI innovation.. Find out more about OpenAI Foxconn domestic AI hardware manufacturing overview.

Broader Economic Ripples Across the Tech Sector

The successful execution of this high-profile partnership is anticipated to generate significant economic reverberations across the broader technology and industrial sectors within the United States. The initiative inherently requires broadening the sourcing of various sub-components and chipsets, which encourages investment and expansion among smaller, domestic suppliers who can meet the stringent requirements of AI hardware production. Furthermore, the commitment to U.S.-based assembly and testing will drive job creation in advanced manufacturing and engineering roles across the states where Foxconn operates. The precedent set by OpenAI and Foxconn validates the commercial viability of building the next generation of mission-critical computing hardware domestically, which will likely encourage other large technology firms to explore similar supply chain de-risking and reshoring strategies to secure their own future compute needs. This could catalyze a long-term revitalization of high-tech industrial capabilities across the nation. To see how this compares to historical tech investment trends, check out this analysis on US industrial policy in the 21st century.

Key Takeaways and Actionable Insights for Tech Watchers

This collaboration is more than a simple supply agreement; it’s an architectural roadmap for the next three to five years of AI. Here are the non-negotiable takeaways:. Find out more about Co-designing successive generations of AI data center racks definition guide.

- Parallel Development is the New Norm: Expect less reaction time from hardware providers. Future infrastructure will be co-designed in parallel with model development, meaning the speed of hardware evolution is now directly tied to the speed of software research.

- The “Back of the Box” Matters Most: The localization focus on power, cooling, and networking proves that bottlenecks for AI scaling are now shifting from the GPUs themselves to the often-neglected support systems. Keep an eye on innovation in advanced power delivery systems.

- Automation is Non-Negotiable: The partnership with Intrinsic shows that scaling U.S. manufacturing for high-volume, complex electronics requires an immediate and deep integration of AI-powered robotics. The factory floor is getting its own AI upgrade.

- Stargate is the Anchor: The scale of the Stargate initiative ($500B+) provides the massive, consistent demand signal necessary to justify Foxconn’s multi-billion-dollar domestic investment and capacity ramp-up to 2,000 racks per week by 2026.

For industry professionals, the actionable insight is clear: If your sub-component or specialized service (like thermal management or high-speed fiber) aligns with the needs of these *domestic* manufacturing hubs, the commercial runway just got significantly longer and more stable. The entire ecosystem is being rebuilt for resilience and speed, prioritizing onshoring over just-in-time global sourcing.

What part of this domestic infrastructure pivot do you think will be the hardest to scale—the specialized cooling or the skilled robotics integration? Let us know your thoughts in the comments below, and don’t forget to sign up for our newsletter to track the impact of these massive US technology investments!

![Pope Leo XIV AI homily directive: Complete Guide [2026]](https://tkly.com/wp-content/uploads/2026/02/pope-leo-xiv-ai-homily-directive-complete-guide-20-1771758410795-150x150.jpg)